Case Study

Client: Alexander Dennis Limited | Sector: Automotive

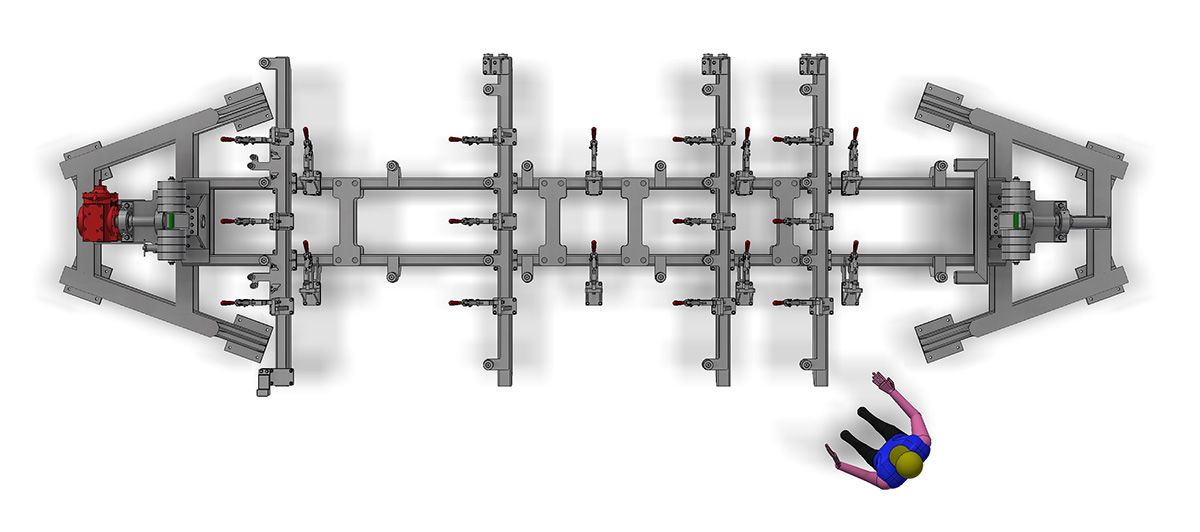

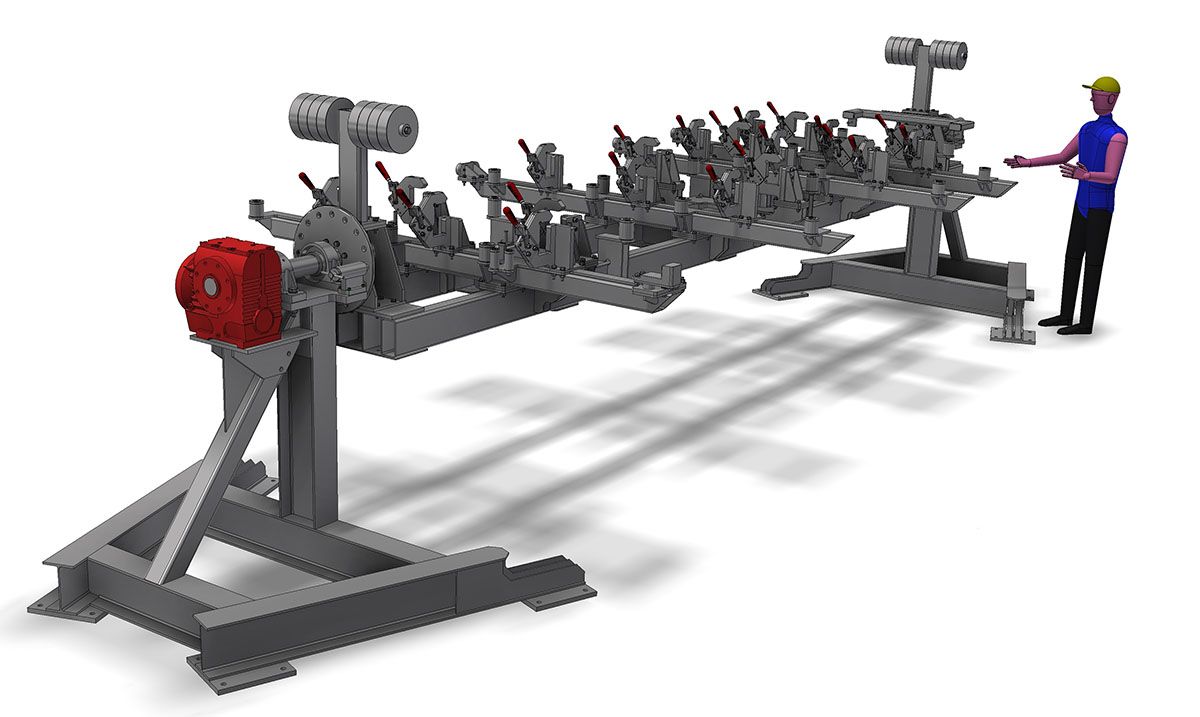

360⁰ COACH CHASSIS WELDING JIG

ADL is a global leader in the design and manufacture of double deck buses and is also the UK’s largest bus and coach manufacturer. ADL offers single and double deck buses under the Alexander Dennis brand as well as Plaxton coaches, with vehicles in service in the UK, Ireland, Europe, Hong Kong, Singapore, New Zealand, Mexico, Canada and the United States.

The Challenge

Summary

As our longest repeat client, Alexander Dennis Limited has, over the years, taken delivery of over forty welding jigs from Skapandi and the 360 degree rotating coach chassis jig is by far the largest. ADL required a solution that meets the following criteria: repeatable, accurate and ease of use for the end operator. This time though access was required for all sides and top and bottom areas that meant we needed to make the jig fully rotatable so access for welding was possible.

The Solution

In Detail

Well versed in the requirements from previous contracts, Skapandi set about reviewing the client supplied completed chassis fabrication 3D CAD models; from this we reverse engineered the best way to load / unload components and also to assess the welding requirements and positions to ensure that all sub components are easily accessible for the operator. The final jig rotates a continuous 360 degrees to allow access to the sub components contained within.

The initial optioneering exercise was undertaken to characterise top level design requirements such as module mounting orientation. Similarity of mounting pads and bolt mounting design was another key criteria that we identified to aid in the upkeep, performance and maintenance of the jig. Furthermore, the final design utilised machined sub components which are replaceable as spares.

The Result

Outcomes

Following onsite assembly we tested the final product by taking delivery of the physical chassis components to load in to the jig and perform a test weld of the final chassis and to also check the release of the final assembly. The final product was delivered to ADL and then subsequently transported to the final destination in the USA.

Other Case Studies

Have a question?

Get in touch

If you would like to discuss your sub contract CNC machining needs or talk to us about your next engineering challenge or product then your dedicated Skapandi engineer is only a phone call away.